What is a Fuel Rail Pressure Sensor?

A fuel rail pressure sensor is a vital part of your car’s engine system. It constantly monitors the pressure of the fuel delivered to the engine. This information tells the engine computer (ECU) exactly how much fuel the engine needs, ensuring efficient operation.

How does a fuel pressure sensor work?

In modern vehicles, fuel pressure sensors play a critical role in monitoring and controlling the fuel system. The sensor uses a special mechanism to convert pressure into an electrical signal. This mechanism can be based on a pressure-sensitive material or vibrations caused by pressure. This signal is then sent to the engine control unit (ECU), which uses it to adjust and optimize the fuel-air mixture ratio and engine performance. The objective is to maintain an optimal fuel pressure for the current operating conditions of the engine to ensure efficient combustion and minimize emissions.

Where is the fuel pressure sensor located?

The location of the fuel rail pressure sensor can vary by car, but it’s typically found near the fuel rail. The fuel rail is a metal bar that acts like a highway for fuel, delivering it to the injectors. This makes it the ideal spot to measure the pressure of fuel entering the engine. A small hose connects the sensor to the fuel system, allowing fuel to flow through it for measurement. Some sensors even include a built-in temperature sensor to account for fuel density changes caused by temperature variations, ensuring the ECU receives accurate pressure readings regardless of fuel temperature.

A healthy fuel pressure sensor is vital for your car’s performance because it ensures optimal fuel delivery, engine efficiency, and reduced emissions. Over time, impurities in the fuel system can clog or damage the sensor, leading to inaccurate readings and affecting engine performance. Regular maintenance and inspection can help identify these issues before they cause problems. A malfunctioning sensor may also trigger a check engine light and cause drivability issues. If this happens, replacing the sensor is essential to restore proper fuel system operation.

Importance of a Fuel Rail Pressure Sensor

Imagine your car having a perfect fuel gauge, not just for the tank, but for the engine itself. That’s what the fuel pressure sensor does. It gives the engine computer (ECU) the precise information it needs to deliver the exact amount of fuel for any driving situation. This translates to better gas mileage, cleaner emissions, and smooth engine performance for you.

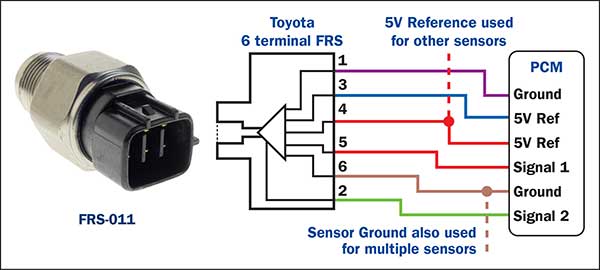

Fuel Pressure Sensor Diagram

This sensor measures the pressure of the fuel supplied to the injectors. It is typically located on the fuel rail, a pipe that distributes fuel to the individual fuel injectors in the engine. The pressure sensor is a critical component that helps ensure the right amount of fuel is delivered to the engine for optimal performance and fuel efficiency.

Electrical Connections

The fuel pressure sensor generally has three electrical connections, as shown in the diagram:

- Supply voltage: Wire carries voltage from the power control module (PCM) or the engine control module (ECM) to the sensor.

- Ground wire: This is the negative connection, often connected to the chassis or the engine block, which provides a return path for the electrical current.

- Signal wire: This wire carries the signal from the sensor back to the PCM or ECM. The signal is a voltage that varies proportionally with the fuel pressure.

Power Control Module (PCM) or Engine Control Module (ECM)

These are the car’s computers. They interpret the signal from the fuel pressure sensor to adjust the operation of the fuel pump and fuel injectors.

- Fuel Pump: The fuel pump moves fuel from the tank to the fuel rail. The PCM or ECM adjusts the operation of the fuel pump based on the signal from the fuel pressure sensor.

- Fuel Injectors: These valves open and close to allow fuel into the engine cylinders. The amount of fuel allowed is adjusted based on the signal from the fuel pressure sensor.

What causes a fuel pressure sensor to go bad?

There are a few reasons why a fuel pressure sensor might go bad:

- Corrosion: The fuel pressure sensor is constantly exposed to fuel, which can cause corrosion over time. This can damage the sensor and prevent it from accurately measuring the fuel pressure.

- Debris: Dirt, dust, or other debris can damage the fuel pressure sensor and prevent it from working correctly.

- Vibration: The fuel pressure sensor is located on the engine constantly vibrating. This vibration can, over time, damage the sensor and cause it to fail.

- Age: The fuel pressure sensor is a worn item that will eventually wear out and must be replaced.

If you suspect that your fuel pressure sensor is bad, there are a few things you can do to check it:

- Check the engine light: If it is on, it could indicate a problem with the fuel pressure sensor.

- Scan the computer: A mechanic can use a scan tool to check the fuel pressure sensor for codes. If there are codes present, it could be a sign that the sensor is bad.

- Inspect the sensor: A mechanic can visually inspect the fuel pressure sensor for signs of damage, such as corrosion or debris.

If the fuel pressure sensor is bad, it must be replaced. This is a relatively simple repair that a mechanic can do.

What are the symptoms of a faulty fuel rail pressure sensor?

What are the common signs of a bad fuel pressure sensor?

Common signs of a bad fuel pressure sensor include:

– Decreased engine performance

– Lowered fuel efficiency

– Difficulty in starting the engine

– Engine misfire or stalling

– Check Engine light activation

How to Test a Fuel Rail Pressure Sensor With a Multimeter?

Diagnosis can be accomplished using a multimeter, a tool that measures electrical properties. It’s essential to follow a systematic approach when testing the sensor:

1. Acquire the necessary tools: Alongside the multimeter, ensure you have an essential toolkit that includes screwdrivers, wrenches, and safety gear.

2. Locate the sensor: You can typically find the sensor mounted on the fuel rail.

3. Disconnect the sensor: Disconnect the sensor from the wiring harness.

4. Measure resistance: Set your multimeter to the ohms setting and measure the resistance across the sensor’s terminals.

5. Interpreting the readings: Consult your vehicle’s manual to understand the readings. The sensor is likely faulty if the measurements do not match the specified range.

What to Do if a Fuel Rail Pressure Sensor Test Fails

If your sensor has failed the test, consider replacing it. Avoiding sensor replacement could lead to declining engine performance, decreased fuel efficiency, and increased emissions.

How to Replace a Fuel Rail Pressure Sensor

Replacing the sensor involves a step-by-step process:

1st Step: Prepare your tools:

- New fuel rail pressure sensor

- Essential toolkit (wrench, screwdriver, etc.)

- Safety glasses

- Gloves

2nd Step: Locate the sensor

The fuel rail pressure sensor is usually located on the fuel rail, a metal tube that runs along the top of the engine. The sensor will have a connector that plugs into the wiring harness.

3rd Step: Disconnect the sensor from the wiring harness

Use a wrench to loosen the connector on the sensor. Be careful not to damage the connector or the wiring harness.

4th Step: Remove the old sensor

Use a wrench to unscrew the old sensor from the fuel rail. Be careful not to damage the sensor or fuel rail threads.

5th Step: Install the new sensor

Screw the new sensor into the fuel rail by hand. Do not over-tighten the sensor, as this could damage it.

6th Step: Reconnect the sensor to the wiring harness

Use a wrench to tighten the connector on the sensor. Ensure that the connector is secure and that there are no loose wires.

7th Step: Avoid common mistakes

- Make sure that you use the correct new sensor for your vehicle.

- Do not over-tighten the new sensor.

- Be careful not to damage the wiring harness.

Some additional tips for replacing the fuel rail pressure sensor:

- If you are uncomfortable replacing the sensor, you can take your car to a mechanic.

- Ensure you have the correct tools and safety gear before starting work.

- Be careful not to over-tighten the new sensor, which could damage it.

- If you damage the wiring harness, you may need to replace it.

How to Bypass A Fuel Rail Pressure Sensor?

Bypassing the fuel pressure sensor can be a great way. Let’s discuss the process, its benefits, and the necessary tools and steps to do it safely.

How to Reset Oil Life on Jeep Cherokee? [Step-by-Step Guide]

1. Diagnosing Issues

The fuel rail pressure sensor is essential to a vehicle’s fuel system. It is responsible for measuring the fuel pressure in the fuel rail and sending a signal to the ECU. The ECU then uses this signal to adjust the fuel injection rate to ensure optimal performance.

It can cause various vehicle performance issues when it is not functioning correctly. These issues can range from reduced fuel economy to engine misfires and stalling. Therefore, it is essential to diagnose any problems with the sensor as soon as possible.

How?

Follow these steps:

Check Fuel Pressure

First of all, you need to check the fuel pressure. This can be done by connecting a fuel pressure gauge to the fuel rail and inspecting the pressure. If the pressure is lower than expected, it could indicate a problem with the fuel pressure sensor.

Check Wiring and Connectors

The next step is to check the wiring and connectors of the sensor. If the wiring is damaged or the connectors are loose, it could cause the sensor to malfunction. If this is the case, the wiring and connectors should be replaced.

The sensor can also be tested with a multimeter. This will help to determine if the sensor is functioning properly. If the multimeter shows the sensor is not working correctly, it should be replaced.

Finally, a scan tool can test the fuel rail pressure sensor. This will help determine if the sensor sends the correct signal to the ECU. If the signal is incorrect, it could indicate a problem with the sensor or the ECU.

How to Test Purge Valve with Multimeter? [DIY Guide]

Diagnosing issues can be a complex process. However, it is essential to identify and address any issues with the sensor as soon as possible. Doing so can help to ensure optimal performance and fuel economy from the vehicle.

2. Disconnecting the Fuel Pressure Sensor

The fuel rail pressure sensor is typically located near the fuel rail and is connected to the fuel rail by a fuel line. When it is disconnected, it can cause various problems with the vehicle’s fuel system. For example, the fuel pressure may become too low, resulting in poor engine performance and fuel economy. Additionally, the sensor is responsible for providing the correct fuel pressure to the fuel injectors, so when it is disconnected, the fuel injectors may not be able to function correctly.

Precautions for disconnecting the fuel pressure sensor

Taking safety precautions is essential when disconnecting the fuel pressure sensor. First, the vehicle should be turned off, and the ignition key should be removed. Then, the fuel line should be disconnected. After disconnecting the fuel line, the sensor should be removed from the fuel rail.

Check for signs of damage

Once the fuel pressure sensor is removed, it should be inspected for any signs of damage or wear. The fuel pressure sensor should be replaced if any damage is found. If the fuel pressure sensor is in good condition, it should be re-installed and reconnected to the fuel rail.

Reconnect the fuel line to the sensor

Finally, the fuel line should be reconnected to the fuel rail pressure sensor, and the vehicle should be started. The fuel pressure should be checked to ensure it is at the correct level. If the fuel pressure is not at the proper level, the fuel rail pressure sensor may need to be adjusted or replaced.

In summary, disconnecting the fuel rail pressure sensor can cause various problems with the vehicle’s fuel system. It is essential to take the necessary safety precautions when disconnecting the sensor and to inspect it for any signs of damage or wear. After the fuel rail pressure sensor is re-installed, the fuel pressure should also be checked to ensure it is at the correct level.

Do Teslas Have Transmissions? Let’s Find Out

3. Installation

Installing an aftermarket fuel rail pressure sensor is a great way to monitor and adjust the fuel pressure in your vehicle’s fuel system. This type of sensor can help you ensure your engine runs efficiently and safely. It can also help you detect any potential problems with your fuel system before they become serious.

Locate the fuel rail

The first step is to locate the fuel rail on your vehicle. This is typically located near the engine and is connected to the fuel injectors. Once you have found the fuel rail, remove the fuel injectors from the rail. This can be done using a wrench or socket to loosen the fuel injector bolts. Once the fuel injectors are removed, you can install the sensor.

Connect the sensor to the fuel rail

The next step is to connect the sensor to the fuel rail. This is done using a special adapter designed to fit the fuel rail. The adapter will then be connected to the sensor using a set of screws. Once the adapter is securely connected to the sensor, you can then attach the sensor to the fuel rail.

Connect wiring harness

Once the sensor is securely attached to the fuel rail, you can connect the wiring harness to the sensor. This is done by connecting the wiring harness to the sensor and the fuel rail. Once the wiring harness is securely attached, you can connect the power source to the sensor. This is typically done by connecting the power source to the fuel rail.

Start the vehicle

Once the power source is connected to the sensor, you can turn on the engine and start the vehicle. The aftermarket sensor should now be able to monitor the fuel pressure in the fuel system. If you notice any problems with the fuel pressure, you can adjust the pressure using the sensor.

How to Stop Your Car from Being Towed: A Driver’s Guide

4. Testing the Improved Engine Performance After the Process

Testing the improved engine performance after the process is essential in improving an engine’s performance. Bypassing the sensor allows the engine to receive a higher amount of fuel, which can result in increased power and efficiency. However, it is essential to test the engine after the bypass to ensure that the increased fuel flow is not causing any adverse effects on the engine.

Connect diagnostic port

The first step is to connect a diagnostic tool to the engine’s diagnostic port. This will allow the technician to monitor the engine’s performance and identify potential issues. Once the diagnostic tool is connected, the technician can start the engine and watch the engine’s performance.

Check fuel pressure

The technician should then check the engine’s fuel pressure. The fuel pressure should be higher than it was before the bypass. The technician should adjust the bypass if the fuel pressure is too low. If the fuel pressure is too high, the technician should reduce the bypass to prevent the engine from running too high.

Check spark plug

The technician should then check the engine’s spark plugs. The spark plugs should be clean and free of any debris or buildup. If the spark plugs are dirty or have buildup, the technician should clean them and adjust the bypass accordingly.

Check the air/fuel ratio

The technician should then check the engine’s air/fuel ratio. The air/fuel ratio should be within the manufacturer’s specifications. The technician should adjust the bypass accordingly if the ratio is too rich or too lean.

Check the engine’s idle speed

Finally, the technician should check the engine’s idle speed. The idle speed should be within the manufacturer’s specifications. The technician should adjust the bypass accordingly if the idle speed is too high or too low.

Once the technician has completed all these tests, they can assess the engine’s performance. If the engine runs smoothly and efficiently, then the bypass has succeeded. If the motor is not running as expected, the technician should adjust the bypass accordingly.

Note that it is critical to test the engine after the bypass to ensure that the increased fuel flow is not causing any adverse effects on the engine. Following the abovementioned steps, a technician can quickly test the improved engine performance after bypassing the fuel rail pressure sensor.

How Long Do Low-Profile Tires Last?

Cost of Replacing a Fuel Pressure Sensor

The cost of replacing the sensor can vary widely, depending on the make and model of your vehicle. It’s essential to factor in the new sensor’s price, and the labor costs involved if you plan to have a professional do the job.

Remember, maintaining a well-functioning fuel rail pressure sensor is paramount for the efficient operation of your vehicle. It helps keep your engine running smoothly and plays a critical role in ensuring optimal fuel economy and minimizing harmful emissions. Keep an eye out for the symptoms of a faulty sensor and take action swiftly if you suspect any issues.

FREQUENTLY ASKED QUESTIONS (FAQs)

#1. Can a Car Run Without a Fuel Rail Pressure Sensor?

A car can run without a fuel rail pressure sensor, but it may not run optimally. The fuel rail pressure sensor is responsible for monitoring the fuel pressure in the fuel rail and sending that information to the engine control module (ECM). Without this information, the ECM may be unable to properly adjust the fuel delivery to the engine, which can result in poor performance, reduced fuel efficiency, and potentially even engine damage.

#2. What Happens If the Fuel Rail Pressure Sensor Goes Bad?

If the fuel rail pressure sensor goes bad, it can cause various engine performance issues. The most common symptoms of a bad fuel rail pressure sensor include rough idling, stalling, poor acceleration, reduced fuel efficiency, and even engine misfires. Sometimes, a bad fuel rail pressure sensor can also cause the “Check Engine” light to come on.

#3. What Causes No Fuel Rail Pressure?

There are several potential causes of no fuel rail pressure, including a faulty fuel pump, clogged fuel filter, or a malfunctioning fuel pressure regulator. Other possible causes include a damaged fuel line, a faulty fuel injector, or a problem with the fuel pressure sensor or wiring.

#4. Can you Drive With a Bad Fuel Rail Pressure Sensor?

It is possible to drive with a bad fuel rail pressure sensor, but it is not recommended. As mentioned earlier, a bad fuel rail pressure sensor can cause various issues with the engine’s performance, which can lead to reduced fuel efficiency, poor acceleration, and potentially even engine damage. If you suspect your fuel rail pressure sensor is bad, it is best to replace it as soon as possible to avoid further damage to your vehicle.

#5. Why Would I Need to Bypass a Fuel Rail Pressure Sensor?

You may want to bypass your fuel rail pressure sensor for several reasons. The most common one is a faulty fuel rail pressure sensor. If your sensor fails, it could result in incorrect fuel pressure and send a wrong signal to the ECU, leading to poor vehicle performance. Bypassing the sensor can help you ensure that the correct fuel is delivered to the engine.

#6. Where is the Fuel Rail Pressure Sensor Located?

The location of the fuel rail pressure sensor varies depending on the make and model of the vehicle. Usually, the sensor is located near the fuel rail or the fuel tank.

#7. Will Bypassing the Sensor Affect My Vehicle’s Performance?

If your sensor is faulty and causing poor vehicle performance, bypassing the sensor can help improve fuel efficiency and overall vehicle performance. However, bypassing the sensor may cause the check engine light to come on and could potentially cause damage to the engine if done incorrectly.

#8. Do I Need any Special Tools to Bypass the Sensor?

No, you don’t need any special tools to bypass your fuel rail pressure sensor. All you need is a basic tool kit, a multimeter, and an LED test light to ensure that the fuel pressure in the fuel rail is correct.

#9. How much does it cost to replace a fuel rail pressure sensor?

A: The cost of replacing a fuel rail pressure sensor can vary depending on the make and model of the vehicle, as well as the labor rates of the repair shop. Generally, the cost can range from $100 to $300.

#10. How does a faulty fuel rail pressure sensor affect fuel economy?

A: A faulty fuel rail pressure sensor can cause poor fuel economy as it may not accurately measure the pressure of fuel in the fuel rail, resulting in an incorrect amount of fuel being delivered to the engine.

Disclaimer: It is important to seek professional advice when dealing with topics that can affect the safety and well-being of individuals. It is not advisable to solely rely on information found online.

I agree with your arguments, nicely done.